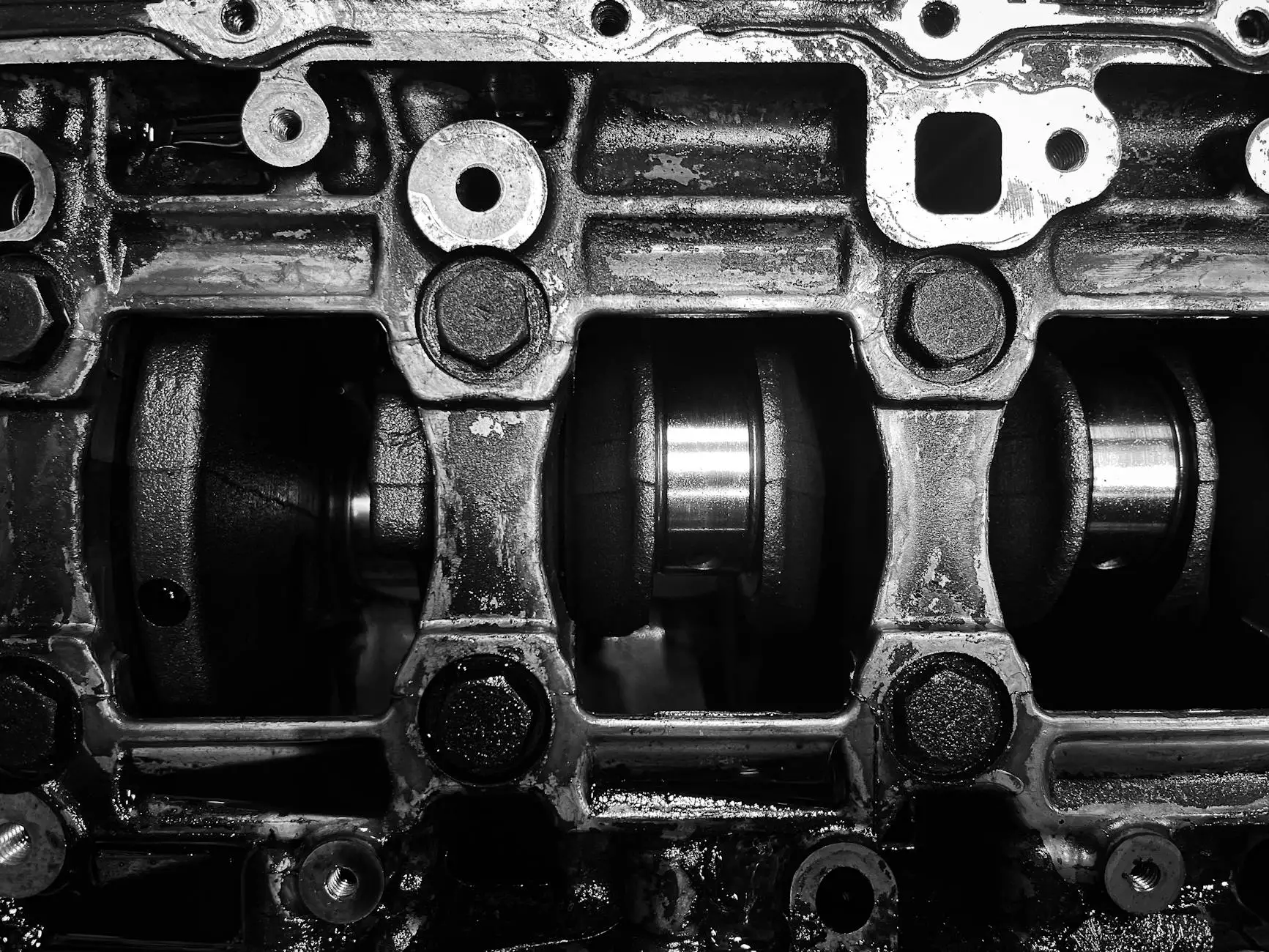

The Integral Role of the **Crankshaft** in Diesel Engines

The crankshaft is a vital component of any diesel engine, acting as the backbone that converts the linear motion of the pistons into rotary motion, which ultimately powers the vehicle. Understanding the parts of the crankshaft is essential not only for mechanics and engineers but also for business owners and operators in the diesel industry who seek to maximize engine performance and longevity.

What is a Crankshaft?

The crankshaft is a long, cylindrical part that transforms energetic movements into usable power. For diesel engines, the crankshaft plays an essential role in the overall operation, making its components crucial for performance and reliability.

Key Parts of Crankshaft

To appreciate the functionality and significance of the crankshaft, it’s important to understand its various parts. Here’s a detailed overview:

- Main Journals: These are the primary bearing surfaces of the crankshaft. They ensure smooth rotation and support the weight of the crankshaft while allowing it to turn in response to the engine's operation.

- Crank Pins: Also known as connecting rod journals, these are the portions of the crankshaft to which the connecting rods are attached. The motion of the piston results in the crank pins rotating around the main journals.

- Counterweights: These are added to balance the crankshaft during its rotation. They help reduce vibrations, ensuring smoother operation.

- Keyways: These slots are machined into the crankshaft to accommodate keys that ensure the proper alignment of rotating parts.

- End Flanges: They are critical for attaching the crankshaft to other components, such as flywheels and pulleys. These provide stability and secure connections within the engine.

The Importance of Understanding Crankshaft Parts

Understanding the parts of crankshaft is not just about mechanics; it's also about business strategies for companies in the diesel engine sector. Here are some reasons why this knowledge is indispensable:

1. Enhanced Maintenance and Repair

For spare parts suppliers like client-diesel.com, providing detailed information about crankshaft components can improve customer service. Understanding the various parts helps in identifying issues and facilitating more effective repairs.

2. Strategic Procurement

Knowing the specific parts of the crankshaft aids business owners in making informed decisions about procurement. It allows them to source high-quality spare parts that are durable and reliable.

3. Performance Optimization

Understanding how the crankshaft functions can drive better performance tuning. By using quality parts, businesses can enhance the operational efficiency of diesel engines, leading to more satisfied customers.

How to Identify Quality Parts of Crankshaft

When dealing with diesel engine parts, it's crucial to differentiate between high-quality components and inferior ones. Here are some tips on how to identify quality:

- Material Analysis: Quality crankshaft parts are typically made from high-grade alloy steel or cast iron, which ensures durability and resistance to fatigue.

- Manufacturer Reputation: Always consider suppliers with a solid reputation in the market. Companies like client-diesel.com are known for their reliable products.

- Certifications: Check for industry certifications and standards that the parts meet, which can be an assurance of quality.

- Precision Engineering: Inspect the machining tolerances. Well-engineered parts will have precise dimensions that ensure a proper fit and function.

Common Problems Associated with Crankshaft Parts

Understanding common issues related to the parts of crankshaft can help businesses prevent costly breakdowns:

1. Crankshaft Wear and Tear

This is a frequent issue, especially in high-mileage diesel engines. Regular inspections and timely replacements of worn-out parts can mitigate this problem.

2. Misalignment

Improperly aligned crankshafts can cause excessive vibration, leading to further damage. Regular checks and balanced crankshafts are essential in preventing these issues.

3. Oil Leaks

Worn seals and gaskets at the crankshaft can lead to oil leaks, which may compromise engine performance and lead to significant repairs.

Maximizing Engine Life Through Quality Parts

Investing in quality parts of crankshaft can dramatically extend the life of diesel engines. Below are strategies to guarantee longevity:

- Regular Maintenance: Establish a proactive maintenance schedule that includes the crankshaft inspection every 10,000 miles. Frequent checks can catch issues before they escalate.

- Use Quality Spare Parts: Always opt for OEM (Original Equipment Manufacturer) parts and trusted aftermarket components that meet or exceed specifications.

- Proper Lubrication: Ensure that all moving parts, especially around the crankshaft, are properly lubricated to reduce friction and wear.

- Engine Tuning: Regularly tune the engine to ensure it is running at optimal levels, thereby reducing stress on the crankshaft and its components.

Conclusion: The Future of Diesel Engine Parts

The parts of crankshaft play a pivotal role in the performance of diesel engines. For businesses in the diesel engine parts domain, such as client-diesel.com, understanding these components can lead to improved maintenance, better procurement decisions, and enhanced customer satisfaction. As diesel technology continues to evolve, focusing on quality parts will remain the cornerstone of operational success.

In summary, taking the time to learn about the anatomy of the crankshaft and its parts can prove to be a worthy investment for any business operating in the diesel engine industry. Whether it’s through sourcing the right components, offering superior customer service, or ensuring your engines remain performant, a sound understanding of the parts of crankshaft is indispensable.

part of crankshaft